2013

2013

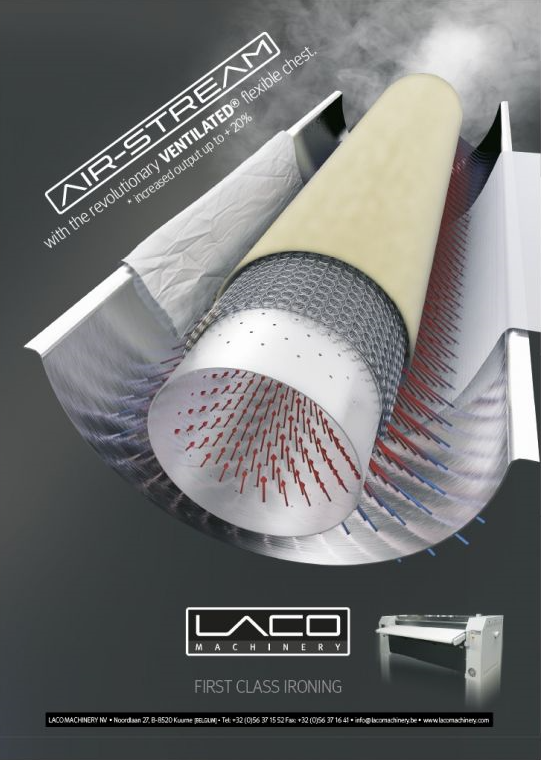

- LACO Machinery designs the patented Air-Stream® chest with increased production capacity. The ironing capacity with the same chest diameter has increased by 20%

- LACO Machinery designs the longer feedingtable for their ironers. The feedbands can be extended by 500mm or 800mm. The feedbands can be driven seperately or driven by the chain from the ironing roll.

- The LACO Machinery logo and website get refreshed with a new style.

- LACO Machinery launches a second brand called SECOMachinery.

This brand is responsible for the smaller production capacities up to 80kg/h.

2014

2014

- LACO Machinery designs the EASY feeder for the M370, D370, M500, D500, D600 and D800 ironers.

- LACO Machinery designs the CROSSBOX.

- The offices get updated.

- LACO Machinery designs the CALORIC (Heat recovery system)

- LACO Machinery gives a new look to the D800. This concept was shown at the exhibition in Milan at Expo Detergo 2014.

2015

2015

LACO Machinery designs 5 new ironers.:

- KING

- D802

- K802

- D803

- K803

- LACO has deliverd their first D802 (Duo 800 roll).